Coconut based charcoal Powdered activated carbon filtration for gases cleaning (PAC filter)

Activated carbon impregnated foam filter is commonly used for air filtration in filters such as range hood filters, room air cleaner filter, vacuum cleaner filters, conditioner filters, commercial air, filters, laser printer/copier filters, hospital/ bank/ restaurant/ print shop/ airports/ gymnasiums/ lounges etc…

Advantages: Low cost, eco- friendly, high structural properties, fire resistance, very high benzene adsorption, high efficiency, suitable for many air and water filtration industries, large filtering surface

Carbon material availability: Bamboo,coconut and coal or wood based carbon

Other features: odor removal, pollution control, High speed in absorbing different gases such as benzene, formaldehyde and ammonia.

Specifications:

- Raw material: open-cell polyether and bamboo,cocoanut and coal or wood based activated carbon

- Porosity: 10~30 PPI(GAC Filter Foam)/10~60 PPI (PAC Filter Foam)

- Iodine value range: 400 – 1100 mg/g

- Activated carbon types: Powdered activated carbon(PAC), Granular activated carbon(GAC)

| ACTIVATED CARBON CHARACTERISTICS | |

| Carbon Content: | 50%~70% (can be adjusted as per requirement) |

| Adsorption Property: | Benzene adsorptive power: More than 90% |

| Deodorization Property: | 1. Ethanethiol: Removal rate ≥ 90% in 30 minutes 2. Trimethylamine: Removal rate ≥ 90% in 30 minutes |

| Heat Resistance: | Working temperature range: -20° C~130° C |

| Force Resistance: | 1. Gas linear velocity 1.0m/s 2. Pressure drop 42PA in 4mm 3. Pressure drop 98PA in 20mm |

| Iodine Value: | 400 - 1100 mg/g |

| PH Value: | 7 - 8 |

| Moisture (Percentage): | 10% |

| Ash (Percentage): | 9% |

| Remark: Some datas above may vary based on different types of activated carbon. |

| RETICULATED FOAM RAW MATERIAL CONSTITUENT | ||

| Polyether/Polyester Glycol | PPG | Water |

| Toluene Diisocyanate | TDI | Colorant |

| Tertiary Amine Compound | AMINE | Tin Catalyst |

| Foam Stabilizer | Olefin Oxide-Polyorganosiloxane | - |

Cell Structure:

Reticulated filter foam operates as a depth-loading filter, as opposed to a surface-loading filter, essentially trapping dust particles within its cells.

The cell structure of filter sponge is remarkable in that each cell has a dodecahedron shape (12 sided), the cell’s walls or “struts” are comprised entirely of organic polymers (polyurethane, polyether, polyester) and the empty space or “windows,” between each strut, comprise 95% – 98% of the filter foam’s mass.

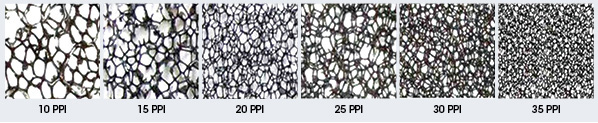

The size, shape & distribution of cells within filter foam can be manipulated during manufacture to provide precisely the desired porosity level, measured in PPI(pores per inch).

10 PPI – 35 PPI pore densities, approximately full scale

Applications:

Activated carbon filter foam can be widely used in daily life and industry such as communication equipment, home appliances, automotive industry, air-conditioner industry, hardware industry, medical equipment industry, instrument tools, bags, furniture, children’s educational toys, physical education equipment, house wares and so on. It’s divided into beginning effect filter foam, amid effect filter foam and high effect filter foam according to the porosity and usage.Concretely, it can be used in filtering, dustproofing, dedusting and adsorbing, etc.

Keywords: Powdered activated carbon foam filter, active carbon reticulated foam, HEPA Filter supplier China, activated carbon foam ball, activated carbon sponge ball, activated carbon foam for waste water treatment,aquarium foam filter sponge, AC pre-filter foam,activated carbon foam filter,active carbon sponge filter mesh,active charcoal foam,active charcoal foam filter,activated charcoal foam,activated charcoal sponge filter mesh.