Open-cell Reticulated Filter Foam is made of polyurethane(PU) foam, with through-hole structure as the base material. It has better aerodynamic performance, small volume density, large specific surface area, high adsorption efficiency, and wind resistance. The coefficient is small. It can be widely used in the treatment of benzene, toluene, xylene and other organic gases, phenols, esters, alcohols, aldehydes and other organic gases and malodorous gases, and various gases with low concentration and large air volume containing trace heavy metals. The exhaust gas can be directly discharged after adsorption, concentration and purification.

Specifications and parameters:

Product features: easy to adjust the pore size, good air permeability, and can be cut arbitrarily.

Conventional size: up to 120*200 (㎝).

Conventional thickness: 3-800 (mm).

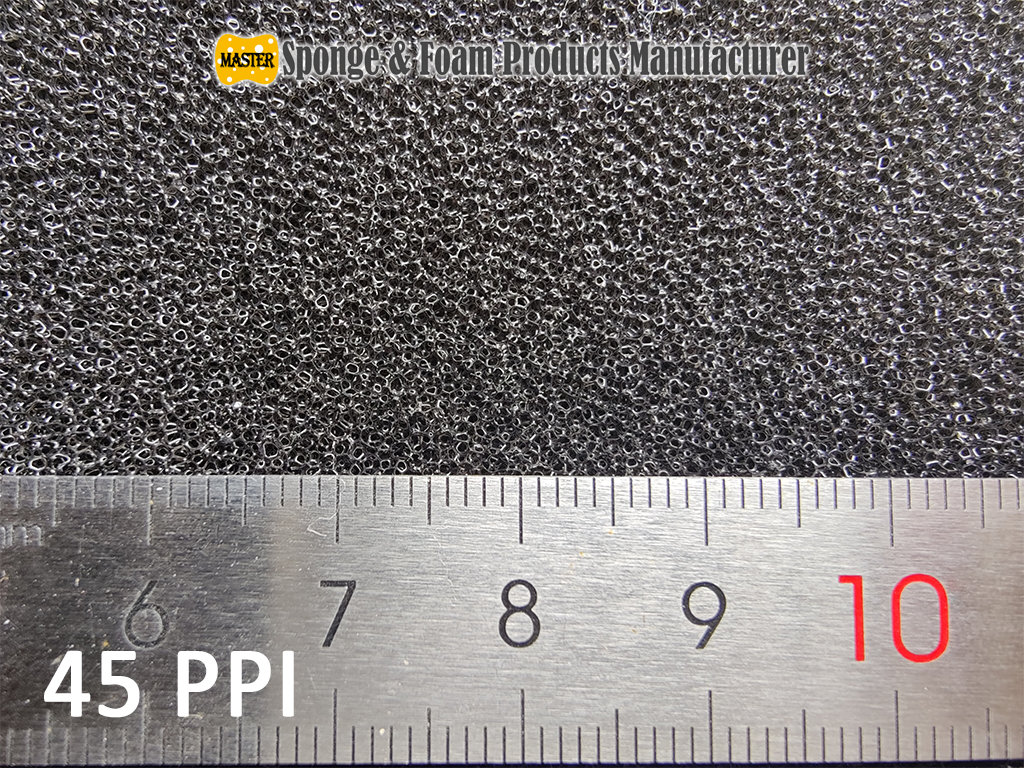

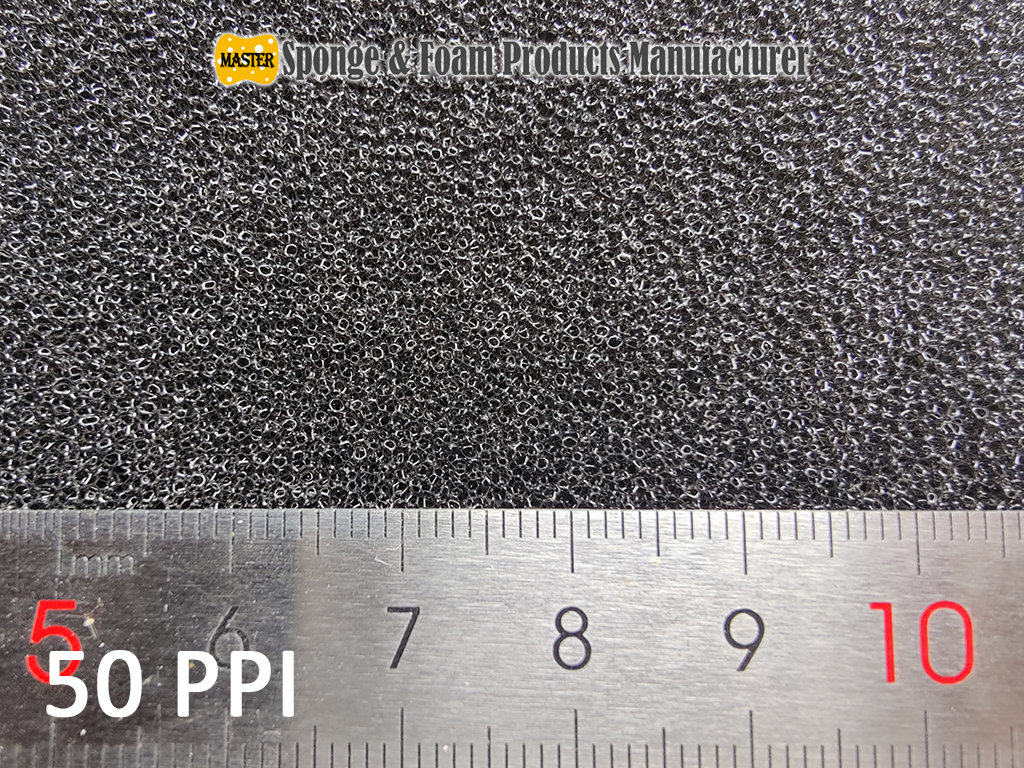

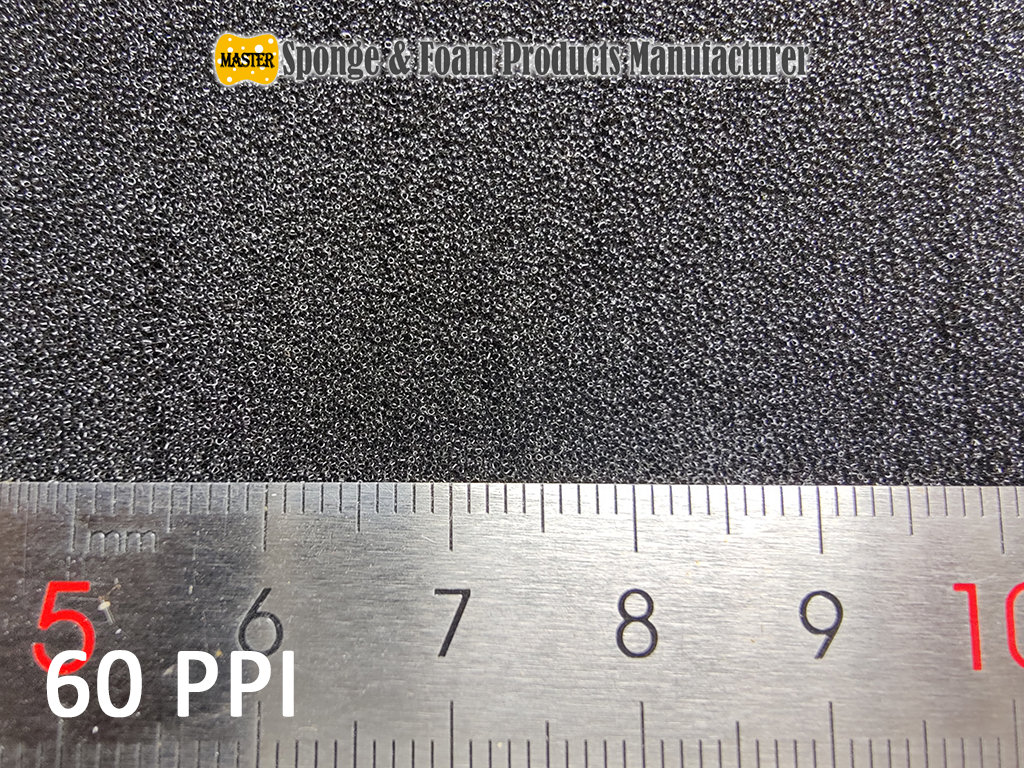

Common pore diameters: fine pores (45-80 PPI), medium pores (25-40 PPI), large pores (10-20 PPI)

Wind resistance: The gas linear velocity is 1.0 m/s, and the pressure drop is ≤42Pa (tested with a 4 mm thick mesoporous filter material.

Product performance:

(1) High opening rate

(2) Good air permeability

(4) Permanent flexibility

(5) Harmless to the human body, no pollution to the environment, no smell

(6) Water resistance, strong drainage after immersion

(7) Recyclable, it is easy to destroy, and there is no secondary pollution to the environment

Application:

Mainly used in the filter layer of air conditioners and air filters of vehicles, aquarium filters, heat-resistant porous mesh ceramics fired with mesh sponges, nickel alloy meshes sintered after electroplating, which can be used as metallurgy Industry filter materials and other uses.

Photos of 10 PPI – 60 PPI foam: